Blog

by SA Label Printers

•

26 March 2024

In the vibrant tapestry of flexographic printing, where precision meets creativity, SA Label Printers stands tall as a paragon of excellence. Our recent accolade of 18 Flexographic Technical Association Awards, including three distinguished honors this year alone, is a shining testament to our steadfast dedication to print excellence. The Essence of Our Craft: Flexographic Technical Association Awards Regarded as the epitome of achievement in flexography, the Flexographic Technical Association (FTA) Awards recognize outstanding performance in our industry. The judging, conducted by a panel of esteemed experts, meticulously evaluates each entry for its print quality, innovative approach, and technical complexity. Triumphing in these awards is not just an achievement; it's a confirmation of our mastery and expertise in flexography. Our Unrelenting Passion for Printing At SA Label Printers, these accolades are not merely trophies; they are reflections of our deep-rooted passion for printing. Like vibrant inks coursing through our veins, our dedication to the craft manifests in every label we produce. Each award-winning piece is not just a label; it's a testament to our attention to detail, our embrace of cutting-edge techniques, and our relentless pursuit of perfection. Our expertise transcends the technical realm. We recognize that a label is more than an identifier; it's a narrative, a connector between the brand and the consumer. Our approach is a blend of precision and artistic flair, ensuring each label we craft not only showcases our printing excellence but also significantly contributes to brand growth and recognition. Beyond Printing: Weaving Brand Stories At SA Label Printers, our role extends beyond the confines of traditional printing. We are the storytellers, the brand enhancers, the creators of visual connections. Our work delves into the soul of a brand, transforming its unique essence into tangible, compelling labels that engage and captivate. Our journey in flexography is more than just printing; it’s not about exciting with first impressions, it's about delighting and creating lasting impressions. Partner with SA Label Printers, and experience the fusion of award-winning expertise, unbridled passion, and creative innovation. Let's not just print labels together; let's craft legacies of excellence that elevate your brand to new heights.

by SA Label Printers

•

26 March 2024

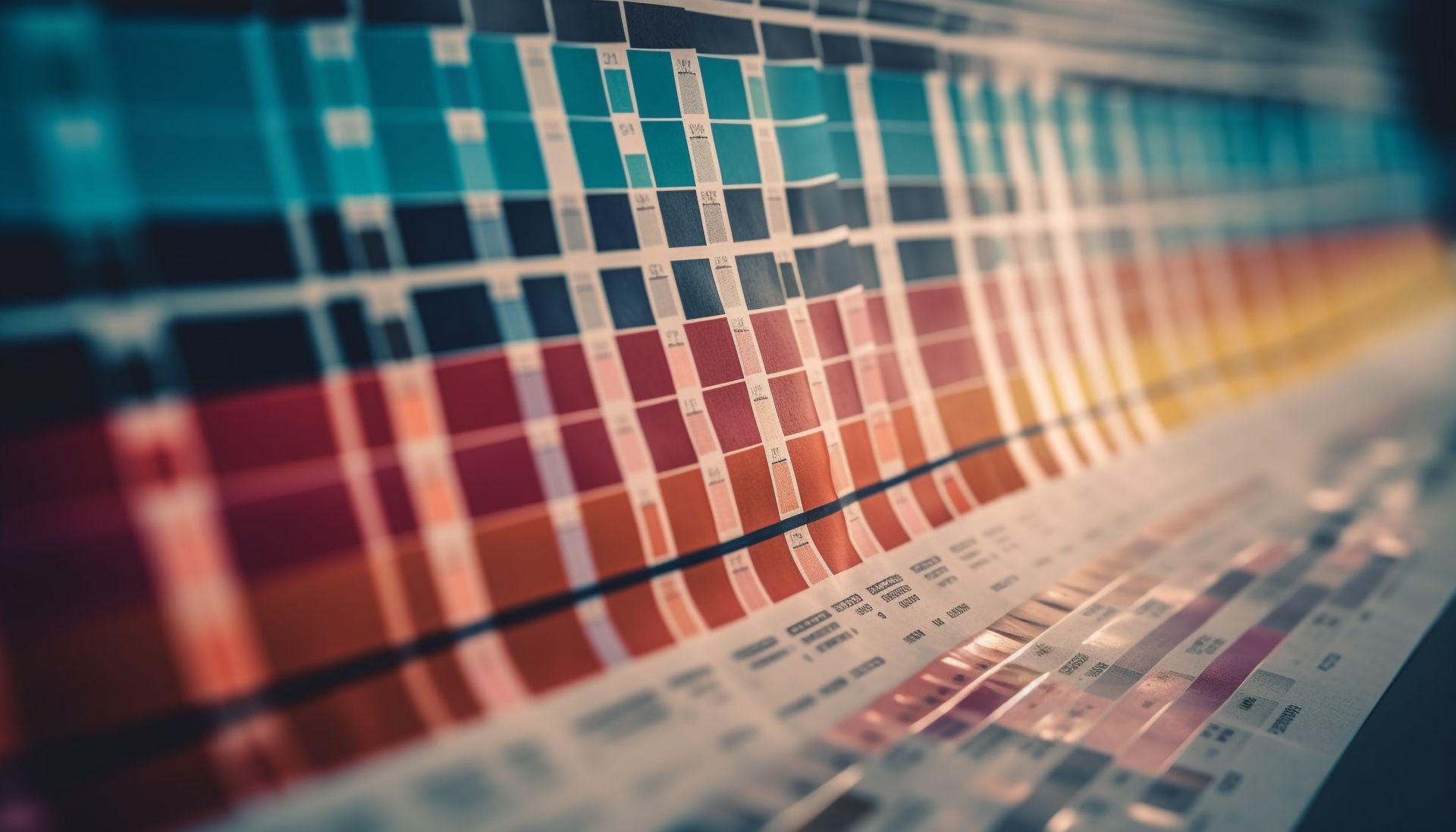

In the vibrant world of flexographic printing, understanding the language of color is essential. At SA Label Printers, we often encounter queries about CMYK and RGB - two color models pivotal in the printing and digital realms, respectively. This article aims to demystify these concepts, especially for those new to the intricacies of flexographic printing, and explain how understanding these color models leads to efficient and cost-effective design processes. CMYK vs. RGB: The Basics RGB (Red, Green, Blue): This color model is used for digital screens. It's based on light, where combining these three colors in varying intensities can produce a wide spectrum of colors. Ideal for digital media, RGB's vibrancy diminishes in print form, as it's not designed for physical mediums. CMYK (Cyan, Magenta, Yellow, Key/Black): In contrast, CMYK is the standard for print. It's a subtractive process, meaning colors are created by subtracting brightness from white. As inks are layered, they absorb or reflect specific wavelengths, creating the desired hues. For flexographic printing, CMYK is the go-to model, as it aligns with the ink used in the printing process. Translating Designs for Flexography When designing for flexographic printing, the transition from RGB to CMYK is critical. Here’s how SA Label Printers ensures this transition is smooth and cost-effective: Consumer Brief to Design: At the outset, understanding the client’s vision is key. Our team engages in detailed discussions to grasp the desired aesthetics, brand guidelines, and color schemes. During this phase, we advise clients on how colors might shift from their digital form (RGB) to print form (CMYK) and work to align expectations with print realities. Design Adaptation: Our design and repro team skillfully adapts the digital RGB designs to the CMYK color model. This step involves color adjustments to ensure that the final printed product remains true to the original vision. It's a delicate balance of maintaining color integrity while adapting to the constraints of the CMYK process. Proofing and Prototyping: Before full-scale printing, we provide color accurate proofs or prototypes. This critical step allows clients to see and approve how their design translates in CMYK, ensuring satisfaction before committing to the full print run. Achieving Cost-Effectiveness The key to cost efficiency in flexographic printing lies in this meticulous preparation and proofing process. By carefully managing the RGB to CMYK transition and ensuring client approval at the prototype stage, we minimize costly revisions and reprints. This proactive approach not only saves time and resources but also ensures the highest quality of the final product. At SA Label Printers, we strive to make the journey from a creative concept to a tangible product seamless and efficient. Understanding the nuances of CMYK versus RGB is just one part of this journey. By entrusting us with your printing needs, you gain a partner adept in navigating these complexities, ensuring your vision is realized in the most vibrant and cost-effective way possible. For any inquiries or guidance on your next flexographic printing project, feel free to reach out to SA Label Printers – where your vision comes to life in the richest of colors.

by SA Label Printers

•

26 March 2024

In the evolving landscape of product manufacturing, the drive towards sustainability is a commendable goal, yet achieving it can be complex. At SA Label Printers, we understand that while the ideal of full sustainability might not always be feasible, incorporating sustainable practices wherever possible is a step in the right direction. Our commitment is to blend sustainability with practicality, offering solutions that are as eco-friendly as they are effective. Balancing Sustainability with Real-World Constraints The journey towards sustainable practices comes with its own set of challenges, primarily due to the additional costs and market readiness. However, this doesn't deter our efforts. Economy of Scale: The more widespread the adoption of sustainable practices, the more affordable they become. As an industry leader, we strive to make eco-friendly options more accessible, aiming to tip the economy scales in favor of sustainability. Investment in Future Benefits: Though initial costs might be higher, the long-term benefits of sustainable practices are significant. We at SA Label Printers view this as an investment in a healthier planet and a more conscientious business model. Our Commitment to Eco-Friendly Practices While full sustainability might not always be achievable, we integrate it into our processes wherever possible. Selective Sustainable Solutions: We offer a range of eco-friendly substrates and inks and advocate for practices that reduce environmental impact, like minimizing waste and recycling. Guidance and Support: For brands prioritizing sustainability, SA Label Printers provides the expertise and resources to make this transition smoother. If sustainability is not yet a focal point for your brand, we can help you explore its advantages and implement it in stages. SA Label Printers: Your Strategic Partner in Labeling With our FSC accreditation and adherence to ISO 9001 and 22000 standards, we ensure responsible, ethical, and high-quality production practices. We understand the nuances of balancing sustainability with cost-effectiveness and market demands. Embrace the journey towards sustainability with SA Label Printers as your partner. Whether fully sustainable solutions are within reach or you're just beginning to incorporate eco-friendly practices, we are here to guide and support you. Contact us today, and let's work together to find the right balance of sustainability, practicality, and innovation for your labeling needs. Your decision to collaborate with us is a step towards a more sustainable, responsible future in the world of product labeling.

by SA Label Printers

•

26 March 2024

Embracing the Future with AI-Driven Innovation at SA Label Printers At SA Label Printers, the integration of Artificial Intelligence (AI) into our operations is not just an upgrade; it's a revolution in product development. We've harnessed the power of AI to transform the trajectory of new product development, turning weeks and months into hours and days. This seismic shift in our workflow means your products are crafted to the highest standards of quality, swiftly and affordably delivered to the market. Our expert team adeptly employs AI technologies, infusing each project with unparalleled efficiency. Tailored Service with a Global Touch At SA Label Printers, personalization is paramount. We don't just provide a service; we immerse ourselves in your brand, catering to a diverse clientele from small, specialized orders to expansive, high-volume productions. Our global perspective and deep commitment to each brand's unique story ensure that no matter the scale of your ambition, we are equipped to bring it to fruition. A Dedication to Creativity and Sustainability Our zeal for creative design is matched only by our commitment to sustainability. We at SA Label Printers believe in the harmony of striking visuals and eco-conscious practices. Our vision is a world where outstanding design and environmental stewardship go hand in hand, and we're leading the charge in sustainable printing solutions. A Passion for Printing Excellence More than a company, SA Label Printers is a collective of passionate professionals devoted to the art of printing. We blend the meticulous craftsmanship of traditional methods with the agility and innovation of modern technology, making us a dynamic force in the printing and design industry, ready to meet diverse client needs with precision and flair. Versatility for Every Vision Whether you're a budding startup or a seasoned corporate entity, our services at SA Label Printers are tailored to meet your specific needs. We thrive on overcoming challenges, big or small, and approach each project with the same level of unwavering commitment and excellence. Your Competitive Advantage Choosing SA Label Printers means more than selecting a service provider; it means gaining a strategic partner. In the competitive market landscape, we are your secret weapon, offering unmatched efficiency, creativity, and a dedication to sustainability. Opt for SA Label Printers as your partner in innovation and excellence. Allow us to enrich your projects with our unique blend of traditional values and modern technological prowess. Together, we can achieve more than just stunning labels; we can craft enduring legacies. Contact us today and let SA Label Printers become the catalyst that propels your brand to remarkable heights.

by SA Label Printers

•

26 March 2024

Flexographic Printing Benefits: • High Speed: Ideal for large runs, offering rapid production once set up. • Economical: More cost-effective for high-volume orders due to lower per-unit costs. • Material Versatility: Can print on various substrates, including paper, plastic, and metallic films. • Durability: Uses inks that are resistant to fading and wear, suitable for labels in demanding conditions. • Ink and Finish Options: Accommodates a range of inks and special coatings. Best For: • Medium to high-quantity label orders requiring durability and special finishes. • Projects with a need for a variety of substrate materials. Digital Printing Benefits: • No Plate Costs: Eliminates plate-making costs and time. • Quick Setup: Faster preparation makes it ideal for urgent and short-run jobs. • Detailed Quality: Provides high-resolution prints perfect for complex designs. • Easy Changes: Allows for easy modifications, suitable for products with multiple versions. • Small-Run Economy: More affordable for low-volume printing without setup costs. Best For: • Short to medium runs with tight deadlines or varying designs. • Products needing high-detail prints or variable data. When planning for the long-term success of your brand, flexographic printing often proves more cost-effective, despite digital printing's initial appeal for its lower upfront costs and flexibility. Flexography excels in high-volume production, offering significant speed and cost benefits as your brand grows. This method becomes increasingly economical with larger print runs, making it an ideal choice for expanding brands. Flexography's adaptability in terms of customization and material choices aligns well with evolving brand needs. At SA Label Printers, we typically advise considering flexography from the outset, especially for brands confident in their market potential. While digital printing is suitable for short to medium runs, flexography is a robust, scalable solution, often the preferred choice for businesses aiming for long-term market presence and growth. Let us help you evaluate your project's specifics to select the most suitable printing method for you.

by SA Label Printers

•

26 March 2024

In the fiercely competitive marketplace, a well-designed label is a critical component of your branding strategy. For marketers, designers, and brand owners, understanding the intricacies of label design—from substrates and inks to finishes and design trends—is essential to creating a product label that not only captivates attention but also positions your brand a cut above the rest. SA Label Printers, with its blend of expertise and innovation, is your ideal partner in this creative endeavor. The Foundation: Choosing the Right Substrate Your label's substrate sets the initial tone for your brand's story. Paper Labels: Best for a natural, artisanal look. Ideal for handcrafted goods or gourmet foods. Plastic Labels: Offer durability and flexibility, suitable for items exposed to moisture, like beverages or bath products. Metallic and Specialty Substrates: Add a touch of luxury and sophistication, perfect for high-end products. The Palette: Selecting the Perfect Ink Inks play a vital role in how your label is perceived. UV Inks: Offer bright colors and durability, ideal for products exposed to sunlight. Water-Based Inks: Eco-friendly options that align with sustainable product lines. The Final Flourish: Finishes and Effects A label’s finish can transform the consumer's tactile experience. Glossy Finish: Creates a vibrant, eye-catching appearance. Matte Finish: Suggests premium quality and elegance. Special Effects: Techniques like embossing or foil stamping can set your product apart. Keeping Pace with Design Trends Staying current with design trends ensures your label resonates with modern consumers. Minimalism: Reflects a brand's honesty and simplicity. Bold Typography: Makes a strong visual statement, enhancing brand recall. Eco-conscious Design: Appeals to the growing market of environmentally aware consumers. Why SA Label Printers? At SA Label Printers, we combine these elements with the latest in printing technology and creative acumen. Our award-winning team works with you to craft labels that capture your brand's essence. Whether it's embracing current trends or pioneering new ones, our solutions are tailored to your unique identity. Our Commitment to Excellence: With an array of Print Excellence Awards and a portfolio featuring renowned brands like Woolworths and Disney, our work speaks for itself. We offer not just labels but a testament to your brand’s quality and market appeal. Join the Ranks of Distinguished Brands: Let SA Label Printers help elevate your product from the commonplace to the extraordinary. We are more than a printing service; we are a partner in your brand’s journey towards success. Don't let your product blend into the background. Contact SA Label Printers today, and let's create a label that does more than identify—it inspires and captivates. Embrace the SA Label Printers advantage and watch as your product becomes the highlight of every shelf it graces.

by SA Label Printers

•

26 March 2024

In the bustling marketplace, a label does more than just identify your product; it's a vital element of your marketing arsenal. At SA Label Printers, we blend art with science to create labels that aren’t just seen but remembered. Let’s delve into the essentials of a successful label and how we can elevate your brand to new heights. The Anatomy of a Successful Label Striking Design: The design is the heart of a label. It should embody your brand's personality, message, and values. Think bold colors for energy, subtle hues for elegance, or playful graphics for fun. Our experienced design team at SA Label Printers knows how to balance these elements to create a label that stands out. Clear Messaging: Whether it's the product name, a catchy slogan, or essential information, clarity in messaging is key. We ensure that your label communicates effectively, making it easy for customers to understand what your product is about at a glance. Quality Materials: The substrate and ink choice can significantly affect the label's look, feel, and durability. With our array of high-quality materials and inks, we can match the perfect combination to your product's needs, whether it's withstanding refrigeration, sunlight, or handling. Functional Adhesives: The right adhesive keeps your label in place under various conditions. Our selection ranges from permanent to peelable, suited for different applications and surfaces, ensuring your label stays put. Legibility and Compliance: Especially crucial for product identification, the text must be legible, and the label must meet industry standards and regulations. We pride ourselves on precision and adherence to compliance, giving you peace of mind. SA Label Printers: Your Trusted Partner At SA Label Printers, we don’t just print labels; we forge brand identities. Our journey with numerous esteemed brands speaks volumes of our expertise and commitment to excellence. Each of our 18 Print Excellence Awards is a testament to our dedication to superior quality and innovation. Brands That Trust Us: Our clientele, including household names like Woolworths, SPAR, and Disney, reflects the trust placed in our capabilities. We cater to various sectors, ensuring that each label we print adds value to the product it adorns. Bringing Your Vision to Life Our approach is holistic. We don’t just listen; we understand. We don’t just print; we innovate. From the initial concept to the final product, we’re with you every step of the way. Our ISO 9001 and ISO 22000 accreditations are not just certificates on our wall; they are the principles that guide our work. Join the Ranks of Successful Brands Your product deserves a label that not only identifies but also captivates. With SA Label Printers, you’re not choosing a service; you’re choosing a partner in success. Be part of a winning legacy. Contact SA Label Printers today and let us help you create a label that does more than identify; it inspires. Trust in our award-winning expertise to make your product shine on the shelves. At SA Label Printers, excellence is not just a goal; it’s our standard. Let us elevate your product with a label that truly represents your brand's essence.

Trusted for over 40 years

across various sectors in South Africa.

Navigation

Working hours

- Mon - Fri

- -

- Sat - Sun

- Closed

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton